Self Fluxing Alloy kalawan maké jeung tahan korosi

Katerangan

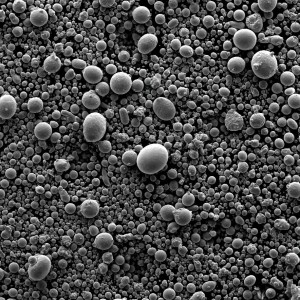

NiCrBSi runtuyan alloy bubuk jeung karasa tinggi teh paling loba dipaké tahan maké jeung korosi bubuk alloy tahan jeung titik lebur lemah sareng suhu lebur bubuk.Cai mibanda fusibility diri alus teuing, wettability sarta kinerja las semprot.Biasana dianggo pikeun tahan korosi sareng tahan ngagem, khususna pikeun panangtayungan preventif sareng perbaikan bagian anu tahan ngageser.

produk sarupa

| merek | Ngaran Produk | AMPERIT | METCO / AMDRY | WOKA | PRAXAIR | PAC |

| KF-Ni15 | NiCrBSiFe | |||||

| KF-Ni25 | NiCrBSiFe | |||||

| KF-Ni35 | NiCrBSiFe | 12 | NI563 | 65 | ||

| KF-Ni45 | NiCrBSiFe | 14 | 69 | |||

| KF-Ni55 | NiCrBSiFe | |||||

| KF-Ni60B | NiCrBSiFe | |||||

| KF-Ni60A | NiCrBSiFe | 335 | 15 / 2001 | NI167 / 1275 | 60 | |

| KF-Ni60AA | NiCrBSiFe | 335 | 15 / 2001 | NI167 / 1275 | 60 | |

| KF-300A | Ni60+35WC-Ni | 36 / 734 | WC562 | 81 | ||

| KF-300B | Ni60A+50WC-Co | 34 / 734 | WC487 | 89 | ||

| KF-300C | Ni60+35WC-Co | |||||

| KF-300D | Self-fluxing basa Nikel Tugsten Carbide |

Spésifikasi

| merek | Ngaran Produk | Kimia (wt%) | Teu karasa | Suhu | Pasipatan & Aplikasi | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | B | Ni | |||||

| KF-Ni15 | NiCrBSiFe | 0.15 | 5 | 2 | 5 | 1 | Bal. | HRC 15 | ≤ 700ºC | Oxy-Acetylene, PTA, HVOF, APS, laser cladding, swa-fluxing, buleud •Molds kaca, bantalan • Teu karasa Low, kateguhan tinggi •Alus lalawanan korosi jeung wetability |

| KF-Ni25 | NiCrBSiFe | 0.20 | 7 | 2.8 | 5 | 1.5 | Bal. | HRC25 | ≤ 700ºC | Oxy-Acetylene, PTA, HVOF, APS, laser cladding, swa-fluxing, buleud •Molds kaca, bantalan • Teu karasa Low, kateguhan tinggi • oksidasi Good sarta lalawanan korosi ogé wetability • machinability Exellent |

| KF-Ni35 | NiCrBSiFe | 0.30 | 9 | 3 | 5 | 2 | Bal. | HRC 35 | ≤ 650ºC | • Kaca molds, bantalan •Piston • korsi klep |

| KF-Ni45 | NiCrBSiFe | 0.45 | 13 | 3 | 10 | 2.5 | Bal. | HRC45 | ≤ 650ºC | • Kaca molds, bantalan •Piston • korsi klep |

| KF-Ni55 | NiCrBSiFe | 0.75 | 15 | 3 | 10 | 3 | Bal. | HRC 55 | ≤ 650ºC | • Kapang •Bantalan •Piston |

| KF-Ni60B | NiCrBSiFe | 0.80 | 17 | 4 | 15 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Bilah kipas • Pipa boiler •Piston |

| KF-Ni60A | NiCrBSiFe | 0.80 | 17 | 4 | 5 | 3.5 | Bal. | HRC 60 | ≤ 650ºC | Oxy-Acetylene, PTA, HVOF, APS, laser cladding, swa-fluxing, buleud • Pistons, conveying rollers, kawat gambar narik roda, Tonjolan screw • karasa High, maké jeung lalawanan korosi |

| KF-Ni60AA | NiCrBSiFe | 0.90 | 17 | 5 | 3 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Gandeng minyak • Roller conveyor • Kawat ngagambar roda tarik, • Screw ékstrusi |

| KF-300A | Ni60A+35WC-Ni | Ni60A+35WC-Ni | HRC65 | ≤ 600ºC | Oxy-Acetylene, PTA, HVOF, APS, laser cladding, swa-fluxing, buleud • Kawat ngagambar roda tarik, bilah, piston, impeller •Leuwih alus lalawanan maké ti Ni60 | |||||

| KF-300B | Ni60A+50WC-Co | Ni60A+50WC-Co | HRC65 | ≤ 600ºC | •mesin bata •Agitasi sédimén • Screw ékstrusi •Parabot tatanén | |||||

| KF-300C | Ni60A+30WC-Co | Ni60A+30WC-Co | HRC65 | ≤ 600ºC | Oxy-Acetylene, PTA, HVOF, APS, laser cladding, swa-fluxing, buleud • Kawat ngagambar roda tarik, bilah, piston, impeller •Leuwih alus lalawanan maké ti Ni60 • partikel Exellent na teuas nyanghareup abrasion sarta lalawanan erosi | |||||

| KF-300D | Self-fluxing basa Nikel Tugsten Carbide | Milik | HRC65 | ≤ 600ºC | Oxy-Acetylene, PTA, HVOF, APS, laser cladding, swa-fluxing, buleud • Kawat ngagambar roda tarik, bilah, piston, impeller •Leuwih alus lalawanan maké ti Ni60 • Ngarobah sorangan • abrasion partikel Exellent sarta lalawanan korosi | |||||